PRE-TREATMENT

Water pre-treatment consists of processes and equipment designed to condition and prepare water before it enters the main treatment or distribution system. The primary goal of pre-treatment is to remove or reduce specific contaminants, particles, and substances that could potentially interfere with the efficiency of the main treatment processes or cause damage to equipment. This can involve various methods such as Softening, Reverse Osmosis, De-Chlorination, De-Ionization, Filtration, and more. Triple Point provides a range of pre-treatment chemicals designed to effectively maintain and prolong the lifespan of these valuable systems and safeguard the purification process.

TYPES OF PRE-TREATMENT SYSTEMS AND CHEMICALS

WATER SOFTENING

Reducing water hardness by removing or exchanging calcium and magnesium ions with sodium or potassium ions. Water hardness, which is caused by the presence of these minerals, can lead to scale buildup in pipes.

Triple Point Treatments for Water Softeners:

Resin Cleaners

Chlorine Removal

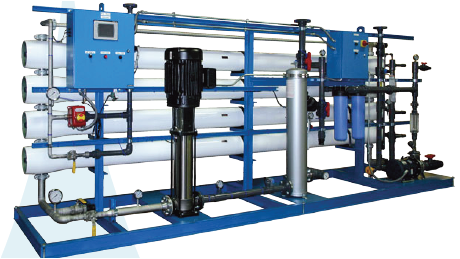

REVERSE OSMOSIS

Reverse osmosis (RO) is a water purification process that utilizes a semipermeable membrane to remove a wide range of contaminants from water. The process involves applying pressure to the water to force it through the membrane, which allows only water molecules to pass while blocking the majority of dissolved solids, ions, particles, and contaminants.

Triple Point Treatments for RO Systems:

Chlorine removal

Anti-Scaling

Metal Scavenger

Bio-dispersant

Cleaning/remediation chemicals

DE-IONIZATION

Often referred to as ion exchange, this is a water purification process that removes ions and dissolved salts from water. This process involves passing water through a resin bed containing positively charged cations and negatively charged anions. The resin selectively attracts and replaces undesirable ions with hydrogen ions (H⁺) and hydroxide ions (OH⁻), forming pure water molecules.

Triple Point is here to keep your pre-treatment systems in check, so you don’t have to!

For further inquiries, click below